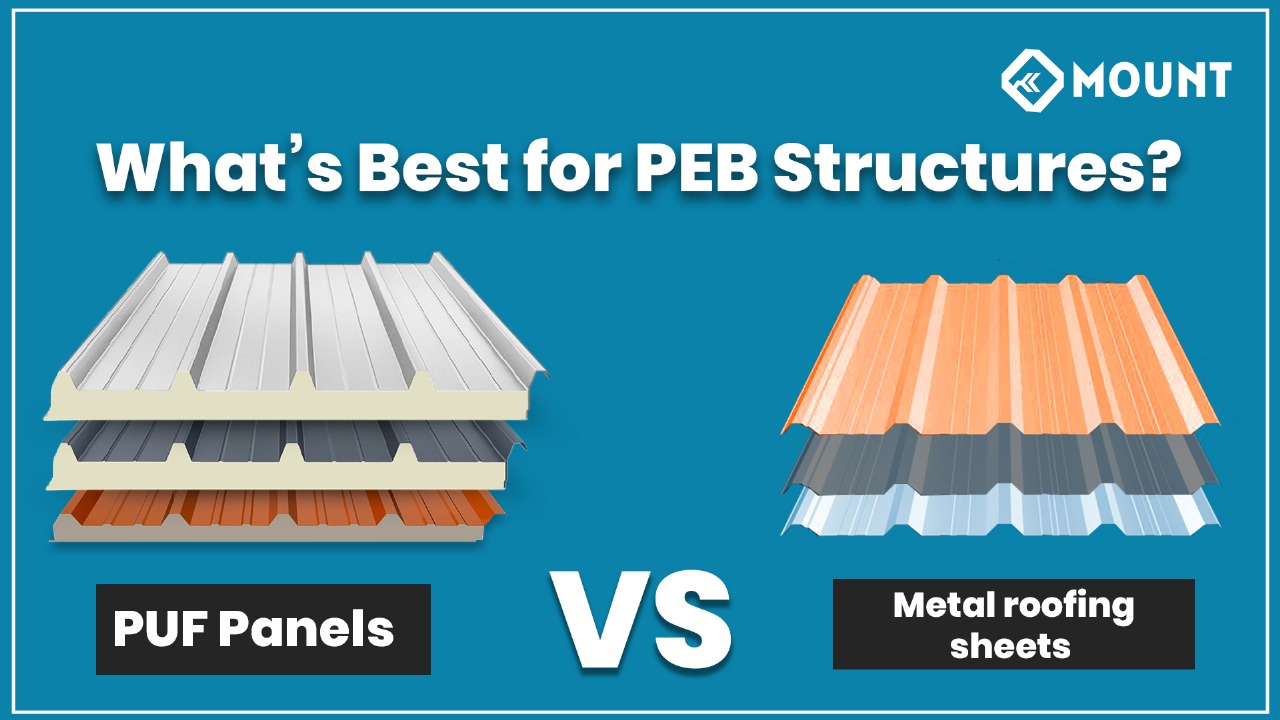

PUF Panels vs. Metal Roofing Sheets: What’s Best for PEB Structures?

When it comes to modern industrial construction, choosing the right roofing solution can make or break your project’s success. Pre Engineered Buildings have revolutionized the construction industry, offering faster assembly times and cost-effective solutions for warehouses, factories, and commercial spaces. However, the critical decision between PUF panels and traditional metal roofing sheets remains a pivotal choice that impacts everything from energy efficiency to long-term maintenance costs. At Mount, we understand that this decision directly affects your building’s performance, operational costs, and overall durability for decades to come.

Understanding PUF Panel Technology

PUF Sandwich Panel technology represents a significant advancement in building materials engineering. These panels consist of a polyurethane foam core sandwiched between two metal sheets, creating a composite structure that delivers exceptional thermal performance. The polyurethane foam core provides superior insulation properties, with R-values typically ranging from 6 to 8 per inch of thickness.

The manufacturing process involves injecting liquid polyurethane between pre-formed metal sheets, allowing the foam to expand and bond permanently with the outer layers. This creates a monolithic structure that eliminates thermal bridging, a common problem with traditional roofing systems. Puf Panel Manufacturer specifications typically guarantee thermal conductivity values as low as 0.022 W/mK, making these panels ideal for temperature-controlled environments.

Traditional Metal Roofing Sheet Analysis

Conventional metal roofing sheets have served the construction industry for decades, offering proven durability and weather resistance. These single-layer systems rely primarily on their material properties and profile design for structural performance. Galvanized steel, aluminum, and pre-painted metal sheets remain popular choices among Pre Engineered Building Construction Company projects due to their lower initial costs and familiar installation procedures.

Metal roofing sheets excel in areas with extreme weather conditions, providing excellent resistance to wind uplift, hail damage, and fire. Their lightweight nature reduces structural load requirements, making them suitable for existing building retrofits. However, thermal performance remains a significant limitation, often requiring additional insulation layers to meet modern energy codes.

Thermal Performance Comparison

The thermal efficiency gap between these roofing systems is substantial. PUF panels deliver integrated insulation performance that eliminates the need for separate thermal barriers. This integrated approach reduces installation complexity while ensuring consistent thermal performance across the entire roof surface.

Pre Engineered Building Manufacturer data shows that PUF panel systems can reduce energy consumption by 30-40% compared to traditional metal roofing with separate insulation. The continuous insulation provided by PUF panels eliminates thermal bridging at structural connections, a common source of energy loss in conventional systems. This superior thermal performance translates directly into lower operational costs throughout the building’s lifecycle.

Installation and Construction Benefits

Peb Construction Company operations benefit significantly from PUF panel installation efficiency. These panels arrive on-site as complete roofing systems, reducing the number of trades required and accelerating project timelines. A typical warehouse roof installation using PUF panels can be completed 40-50% faster than equivalent traditional systems.

The interlocking joint design of PUF panels creates weather-tight seals without requiring additional sealants or gaskets. This self-sealing capability reduces potential leak points and minimizes long-term maintenance requirements. Mount’s project experience demonstrates that PUF panel installations consistently achieve better quality control and fewer callbacks compared to multi-component roofing systems.

Cost Analysis and Long-term Value

Initial investment considerations often favor traditional metal roofing sheets due to lower material costs. However, comprehensive lifecycle cost analysis reveals a different picture. Pre Engineered Building Suppliers report that PUF panel systems typically achieve payback periods of 3-5 years through energy savings alone.

The integrated design of PUF panels eliminates costs associated with separate insulation materials, vapor barriers, and additional labor for multi-layer installations. Furthermore, reduced HVAC equipment sizing requirements in PUF panel buildings can offset significant portions of the premium material costs. Mount’s cost analysis shows total project savings of 15-25% when all factors are considered.

Durability and Maintenance Considerations

Both roofing systems offer excellent durability when properly installed and maintained. PUF panels provide superior resistance to thermal cycling due to their monolithic construction, reducing stress-related failures common in multi-component systems. The foam core also provides excellent sound dampening properties, creating more comfortable interior environments.

Pre Engineered Building Construction Company maintenance schedules typically show 40-60% fewer service calls for PUF panel roofs compared to traditional systems. The sealed panel construction prevents moisture infiltration into insulation materials, eliminating degradation issues that plague conventional systems over time.

Making the Right Choice for Your Project

The decision between PUF panels and metal roofing sheets should consider project-specific requirements including climate conditions, building usage, energy efficiency goals, and budget constraints. For temperature-controlled facilities, cold storage applications, and energy-conscious projects, PUF panels deliver superior performance and long-term value.

At Mount, we recommend PUF panel systems for most modern Pre Engineered Buildings due to their comprehensive performance advantages. While initial costs may be higher, the combination of energy savings, reduced installation time, and lower maintenance requirements makes PUF panels the optimal choice for forward-thinking building owners seeking maximum return on investment.